Hydraulic filtration is the process that includes hydraulic filters to eliminate dirt and contaminants and cleans the oil regularly. Hydraulic filters guard your hydraulic system mechanisms against impairment because of contaminated oil or other hydraulic fluid.

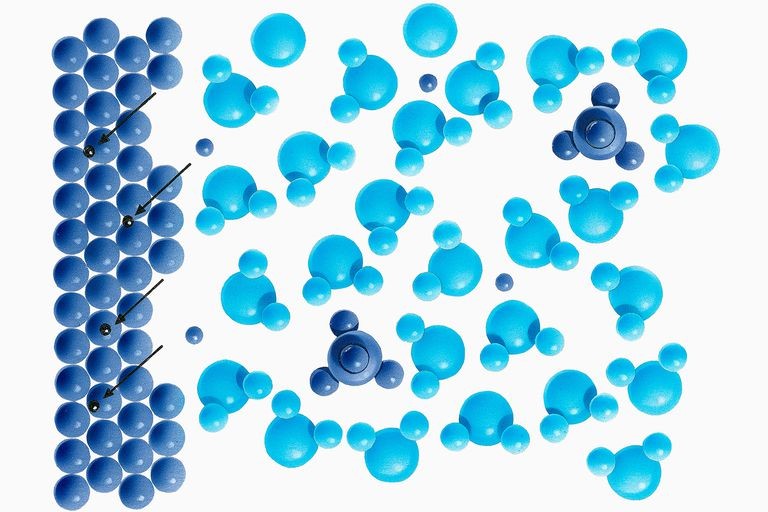

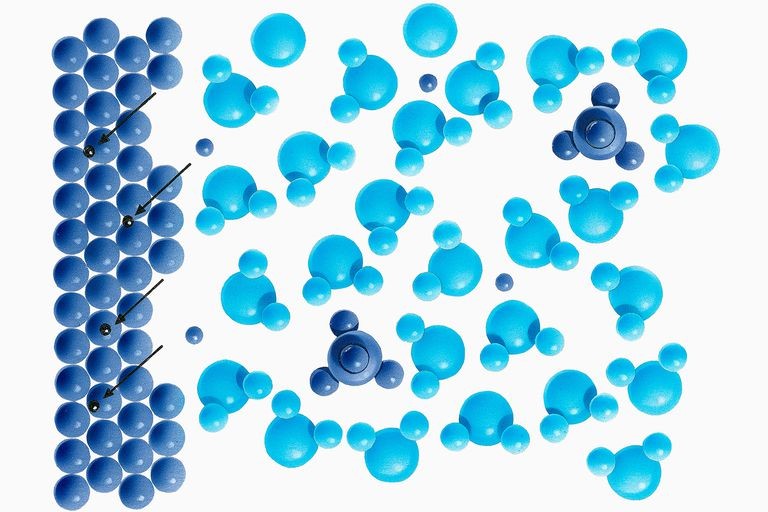

According to the guide hydraulic filtration, about one billion particles larger than 1 micron 0.001 mm or 1 mm go in a hydraulic system. These particles can be the reason for harm to hydraulic system components for the reason that hydraulic oil is easily polluted.

So, preserving a good hydraulic filtration system can increase the lifetime of hydraulic components.

Hydraulic filters work against other functions performs by hydraulic fluids. Those basic functions are:

- Their main function is to produce force and wave as the flow is changed into pressure before getting into use.

- The fluid forms a lid by making a space between metal surfaces that helps in providing a pressure wall and eliminates impurities.

- To remove friction from the metal surface by lubrication.

- Hydraulic fluid also cools down the hydraulic system components.

Basic Uses for Machinery

1. Keep Your Machines Functioning Longer

The foremost use of hydraulic filtration is to extend life a machine on power units that is directly secured to filtered, clean oil.

If you are planning to invest in guide hydraulic filtration system you are aiding to increase your hydraulic component’s life.

A filtration cart eradicates any element from your component’s oil endlessly. Because of double spin-on filter heads, it can filter a variety of elements.

2. Helps in Oil Testing

The correct use if hydraulic filtration system you’ll be able to test and examine the oil or any other fluid you are using. Testing the oil inside your machines will let you know about the contaminants that are troubling your machine is operating properly

consequently, through guide hydraulic filtration, you are filtering your hydraulic equipment habitually and you must be testing your oil properly.

Considering the hydraulic filtration process in our routine conservation will help us recognize all the concerns and possible enhancements of our machines, oil, and fluids.

3. Suitable for Every Location

Because of its portability feature, they can be used at any site; its inflatable tires help them to survive at any place. Its easy conveyance supports to filter hydraulic power unit.

By connecting it to the correct power source allows fluid to filter at any site location. In this case, hydraulic filters are the example of best industrial filters.

4. Remove Dirt Particles On Continuous Basis

A hydraulic filtration process helps to get rid of these particles and clean the oil on an unceasing basis. The performance for every hydraulic filter is restrained by its contamination exclusion competence.

Thus, nearly every guide hydraulic filtration comprises more than one hydraulic filter. The hydraulic filters between pump and actuators are denoted as pressure filters and the hydraulic filters between the actuators and tanks are low pressure or return line filters.

This mechanism of the hydraulic system, filters all the contaminates efficiently and increases productivity.

Along with the uses of guide hydraulic filtration, it is imperative to recognize the sources of contaminants that surely helps in making the process easy.

Contaminants pass in hydraulic systems in many ways.

• It can be transmitted during the industrial and assembling process.

• It can be produced through any normal operation.

• Consumed from outside the system during normal functioning.

If contaminants are not properly filtered, they will be left in the system after the manufacturing process. These pollutants contain dust, welding slag, rubber particles from hoses and seals, sand from moldings, and metal debris from machined workings.

Likewise, when fluid is firstly added to the system, a certain amount of contamination perhaps comes with it. Naturally, this pollution includes many kinds of dust particles and liquid. For filter the liquid we have to use filter liquid bags

More Hydraulic Filtration system

The Common materials used in hydraulic filters are micro-fiberglass, phenolic-impregnated cellulose and polyester. Various systems just require definite replacement filters, which can be ordered through filter producers and dealers.

By the machine system or device constructor, as soon as designing a hydraulic system, it is important to reflect the contaminant presence level of the device. The acceptable drop in pressure instigated by the filter.

These factors will help you in defining the proper filter media, placing and design. The nature of the filter media largely relies on the nature of the contaminants that will be come across by the hydraulic system.

Some systems will also require filters that remove air and water like quality pleated filter bags. Although particulate is repeatedly the primary concern, to that extent, hydraulic filters can take away very small particles from the hydraulic fluid; this can involve contaminants as small as simple micrometers in size.

Conclusion

As soon as working with hydraulic power units and other industrial machines, a filtration system is key to keep your unit functioning efficiently and extend the permanency of your hydraulic system’s life.

This filtration component is dynamic is to save your machines by any damage from oils or other fluid, usually caused by particles that work within.