Filtration systems are a crucial part of the industrial process as without it the equipment is at risk of serious damage. If the particles are not properly filtered out of all the parts of the equipment, it could end up in system failure. Therefore, it is necessary to add filters manufactured to prevent any possibility of metal erosion in any parts of machinery or an overall halt.

Types of the Best Filters Manufactured In the Industry

We have discussed how important filtration systems are for the machinery used in manufacturing. It must be understandable by now that choosing filters manufactured for your particular industry or machine type is pivotal for your factory’s processes.

Being the best industrial filter manufacturer, we create all types of filters in the above par quality to provide you with efficient support. Our intention is to create filters so reliable that your equipment is never at risk. In this article, we are defining each of our filters according to their functions and the suitable industry they are filters manufactured for.

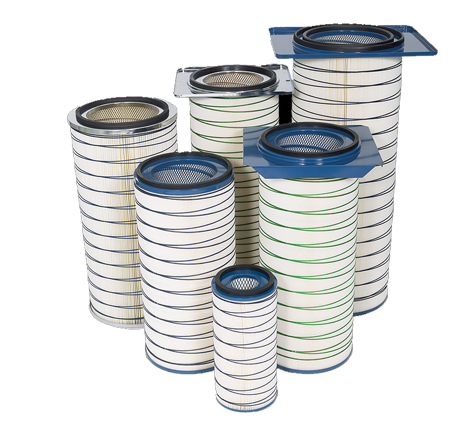

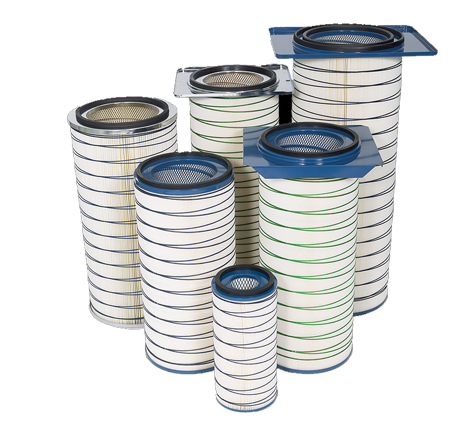

1. Dust Cartridge Filters

Dust cartridge filters are manufactured into a pleated fabric with the main job to obstruct any dust particles to pass through. The pleats are locked down by a unique Helix Bead Wrap that keeps the locks in place individually. This promotes a better filtration process as the cartridge then cleans better than other filters available in the market.

The dust cartridge filters are one of the best industrial filters available in the market. They have a lower energy consumption rate as pulse cleans more effectively even in lower operating pressure drop. These filters are also quite long-lasting with environmentally friendly components that make the dust cartridge filters more sustainable than other filters in the market.

2. Gas Turbine Filters

Gas turbine filters are manufactured with designs that enhance air intake. These conical shaped filters are so efficient that they work efficiently even in the most contaminated environments. Working on the HEPA standard, they extend the overall life of turbines and their operational efficiency.

Due to higher durability and lower resistance than nanofibers, gas turbine filters are one of the best industrial filters for cost-saving. Apart from that, these filters also have the highest capability to hold dust, increasing in the productive hours of your manufacturing unit. Gas turbine filters manufactured by an industrial filter specialist also ensure more durability, corrosion, and weather resistance.

3. Oil Mist Filters

The manufacturing processes produce different types of contaminants in the environment. One of those contaminants is oil mist or oil smoke. It can be highly hazardous for the employees as it can put them on the risk of life-threatening illnesses like cancer and pulmonary diseases.

Therefore, it is crucial for the manufacturing factories that generate oil mist or smoke, to install oil mist filters in their machinery. Oil mist filters not only clean the air of the oil droplets but also prevent them to return back to the air.

The oil droplets are compressed and send back to the lubricant oil tank for reuse. This process not only saves the workers from health hazards but increases the efficiency of your machinery by decreasing the number of times a machine has to be replenished.

4. Nonwoven Filter Media

Nonwoven filter media are not knitted or woven as suggested by the name. These filters are usually created with a fabric that is spun-bound, i.e., woven through continuously spinning filament fibers. Having a nonwoven structure, these filters possess a very high wet strength and are chemically tolerant.

There are six types of nonwoven filter media variants manufactured by DHA Filter to choose from. Each variant has its distinct features and can be used in a variety of functions as per your needs.

5. Pleated Filter Bags

The pleated filter bags are manufactured by industrial filter specialists for liquid filtration. These filters manufactured for high flow capacity are ultrasonically welded with an ‘inside-to-out flow’, keeping the contaminants within the filter. Pleated filter bags can be used pharmaceuticals, steel & power, cement, chemical and other heavy manufacturing industries.

6. Laser Filters

Laser filters or Compact Laser Filters are 100% hydrophobic thermoplastic polymers with distinct qualities that combat chemical degradation. These laser filters are made up of ePTFE (Polytetrafluoroethylene or simply, Teflon), an extremely inert chemical.

Teflon, due to the high chemical inertness, makes laser filters’ application capacity better than others. Therefore, laser filters are widely used for laser cutting, plasma cutting, laser welding, surface treatment, and micro processing.

7. Process Filtration

Process filtration is used for filtering, purifying and separating contaminants for all types of manufacturing processes. By using process filtration products in your manufacturing equipment, you can enable higher product yields. Higher productivity becomes possible as the fluid stream is filtered, becoming more viable in terms of efficiency.

The process filtration can provide solutions for various high-level industries. These applications include fixative/adhesive, oil & gas, cosmetics, minerals, pulp & paper factories. Power-Gen companies also reply to Process Filtration provided by the best industrial filter manufacturers.

8. Hydraulic Filters

The hydraulic components in your manufacturing units need protection from any contaminants as they are sensitive to abrasion. The pumps, motors or valves can get dangerously damaged if these contaminants travel into the system. The hydraulic filters are mainly used in aeronautics, hydraulic, ceramic industries and also in power plants & refineries.

Hydraulic filters are specifically used to remove any particles or water from the oil to prevent early wear & tear of the system. If these precautions are not in place, the system may end up in permanent failure.

9. Compressor Filters

The best industrial filter manufacturers know the importance of compressor filters and provide them in a different variety to suffice customer needs. Air filters, oil filters, and air/oil separators are the different types of compressed filters we provide. Air and oil filters remove contaminants from the environment and lubricants while separators eradicate particles from compressed air.

Every filter is available for its distinct needs and usage while synthetic oil is also provided as a product that carries highly engineered synthetic lubricants. Synthetic oil is used to reduce wear and tear in the critical components of your manufacturing equipment. The overall effect of compressor filters manufactured for optimum performance can be noticed by a lower cost of production.

10. HVAC Filters

HVAC filters or Heating, Ventilating and Air Conditioning filters are used to fulfill your factory’s air quality requirements. These filters are designed to trap indoor pollutants like dust mites, pollen, and other minute contaminants that reduce air quality.

These filters work on the disseminated air in your environment and cleaning it. The air is pulled into the vent, where the HVAC filters start the process of separating and capturing the dust, debris and other airborne particles that contaminate the air.

11. Paint Booth Filters

The dyeing and tanning industry uses spraying methods to paint leather or other materials etc. These spraying processes can suspend a lot of chemicals into the environment that can cause respiratory issues.

Paint booth filters help clean the air by stopping these pollutants from disseminating into the outdoor environment. There are two filtration systems involved in this process, which are integrated for optimum functionality. The overall efficiency of the paint booth process can be enhanced through these filters.

There are several other benefits of the paint booth filters that include good air balance, low cost of cleaning and maintenance.

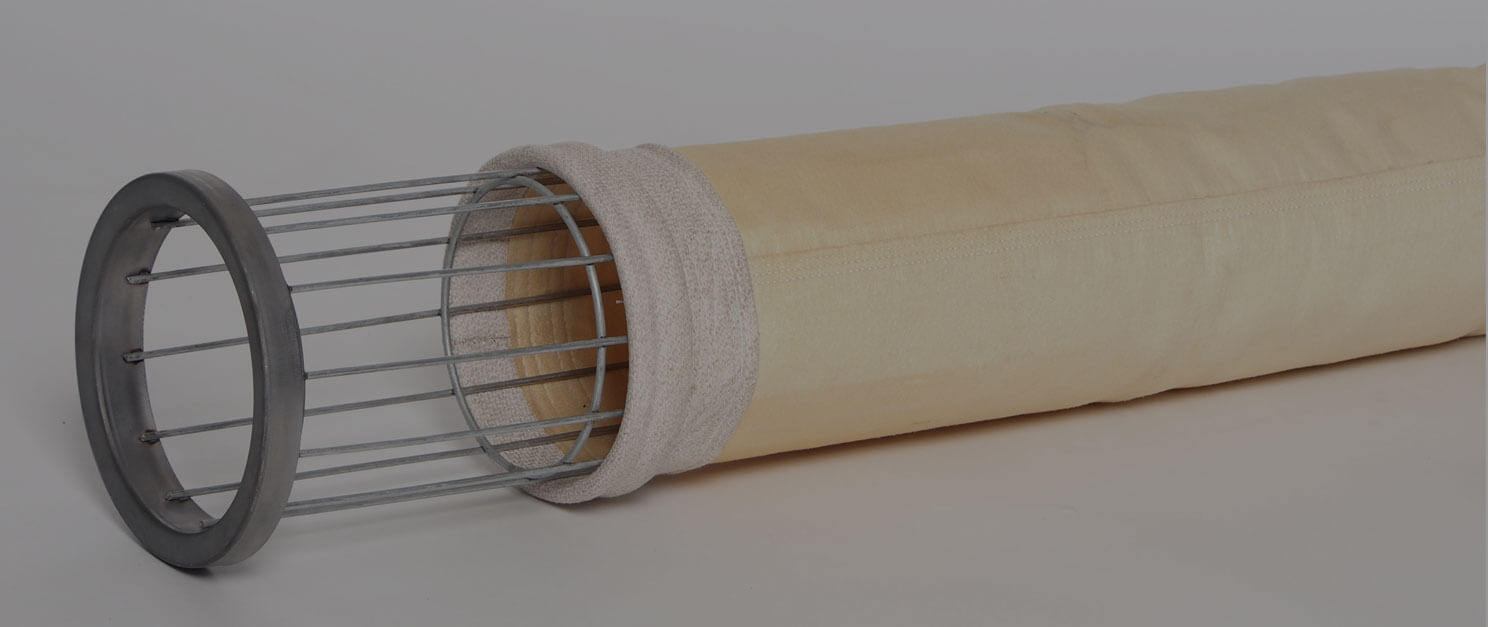

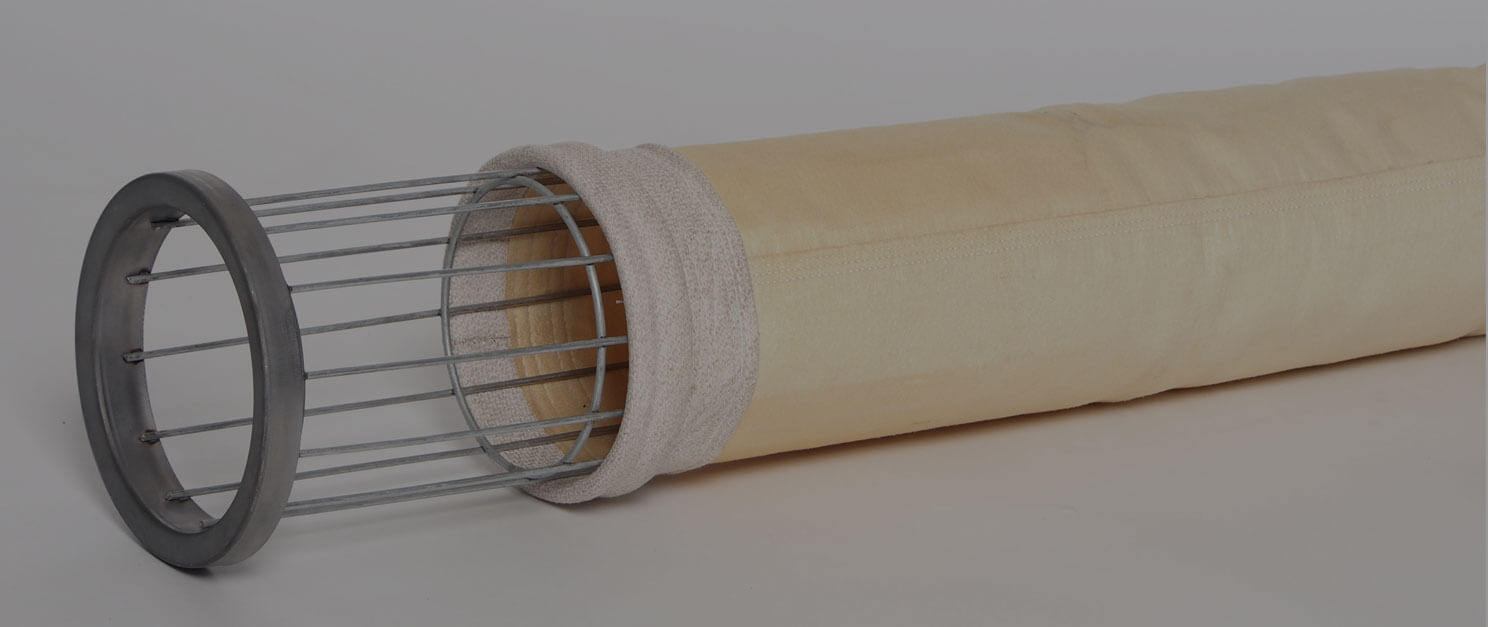

12. Baghouse Filters

Baghouse Filters pull in the dirty air from the environment and filter out pollutants like dust and harmful gases. After clearing the contaminants, it sends the clean air back to the atmosphere.

There are different types of baghouse filters that are manufactured according to the collecting and cleaning systems they will be used for. Our variety of baghouse filters work with Pulse jet, reverse air, and mechanical shaker baghouses.

The material used in baghouse filters can also be customized according to the abrasion resistance, chemical compatibility, and temperature resistance that the cleaning system will have to face.

Conclusion

The industrial manufacturing processes heavily produce pollutants that contaminate your factory’s environment and affect our planet’s atmosphere, resulting in life-threatening diseases. As inhabitants of this planet, we must take the right steps and save it from hazards that destroy it.

Environmental agencies have also emphasized on using precaution to keep the atmosphere healthy for everyone. Using the best industrial filters not only saves the environment but also improves the productivity of your manufacturing units. It is a win-win situation every manufacturer must avail.