Description

POMF 93 Series – High Performance

Liquid Filter Bags – 93% Efficiency

The high performance POMF Series liquid filter bag offers high efficiency, 93% plus, and high contaminant holding capacity at low micron ratings. It can also absorb unwanted traces of oils that frequently occur in processed fluids. The high amount of surface area due to the polypropylene microfiber construction results in excellent oil-holding capabilities.

Design Details

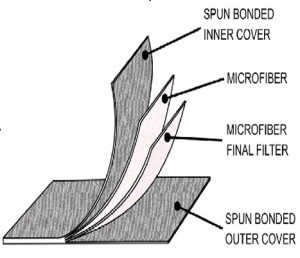

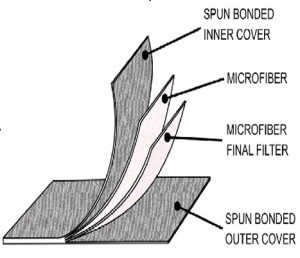

The High Performance Liquid Filter Bag is constructed of polypropylene (POMF) melt-blown microfibers, allowing for very fine particles capture at high efficiencies. All high performance bags are absolute efficient at their suggested micron rating. The bag construction makes this filter an easy to use, convenient, high performance alternative to filter cartridges.

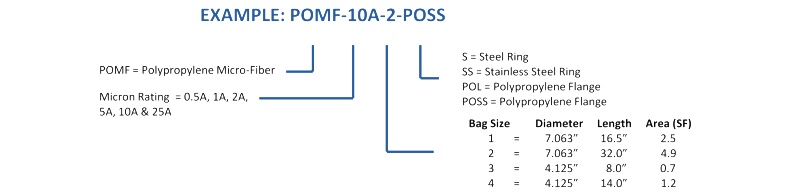

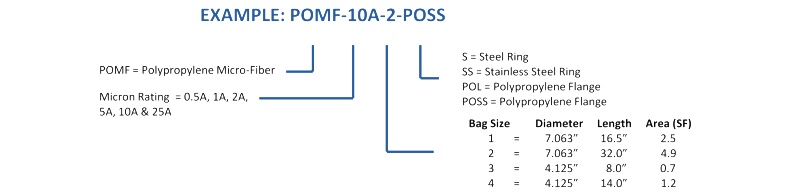

The POMF 93 Series bags are available with carbon steel ring, stainless steel ring or plastic flange. The filter bags are made from polypropylene (POMF) and are free of potentially damaging silicone oils.

The POMF 93 Series filter bag materials comply with CFR Title 21 FDA regulations governing food and beverage contact.

Each layer in the construction of the High

Performance Liquid Filter bag serves to give you

the efficiency and reliability you require.

How to Order DHA Filter POMF 93 Series Bags

Filtration Levels

POMF 93% Series liquid filter bags are absolute efficient at their suggested application rating.

Oil Holding Capacity

POMF (polypropylene) 93% Series liquid filter bags can absorb unwanted trace of oils that occur in processed fluids.

Dirt Removal Capacity

These high performance filter bags are rated using a challenge of AC Test dust in water, and controlled flow rate up to 10 GPM. Efficiency data represent initial efficiencies only.

FDA Acceptability for Food & Beverages

All materials of construction in the POMF 93% Series liquid filter bag are listed as acceptable for potable and edible liquid contact according to CFR Title 21.

| PRODUCT NUMBER | SUGGESTED APPLICATION | RATING EFFICIENCY |

|---|---|---|

| POMF/.5A | 0.5 micron | 93.00% |

| POMF/1A | 1.0 micron | 93.00% |

| POMF/2A | 2.5 micron | 93.00% |

| POMF/5A | 5 micron | 93.00% |

| POMF/10A | 10 micron | 93.00% |

| POMF/25A | 25 micron | 93.00% |

| MATERIALS OF CONSTRUCTION | |

|---|---|

| COMPONENTS | POMF |

| Filter Materials | Polypropylene |

| Coverweb Material | Polypropylene |

| Handles & Thread | Polypropylene |

| Ring Type | Carbon or Stainless Steel Ring or Plastic Flange |

| Bag Sizes | 1, 2, 3 & 4 |

| Silicone Free | Constructed of pure polypropylene free of poten- tially damaging silicone oils. |

POMF ● PEMF 95 Series – High Performance Liquid Filter Bags – 95% Efficiency

The POMF●PEMF 95% Series filter bag is available in polypropylene (POMF) or polyester (PEMF) microfiber, and are

constructed with more layers to provide higher efficiencies.

Design Details

The 95% efficient High Performance Liquid Filter Bag offers you the option of either polypropylene (POMF) or polyester (PEMF) meltblown microfibers to better fit your specific application. Microfiber construction allows for very fine particles capture at high efficiencies. All high performance bags are absolute efficient at their suggested micron rating. The bag construction makes this filter an easy to use, convenient, high performance alternative to filter cartridges.

These high performance liquid filter bags are available with carbon steel ring, stainless steel ring or plastic flange. The filter bags are made from pure polypropylene (POMF) or polyester (PEMF) and are free of potentially damaging silicone oils.

The POMF/PEMF 95% Series filter bag materials comply with CFR Title 21 FDA regulations governing food and beverage contact.

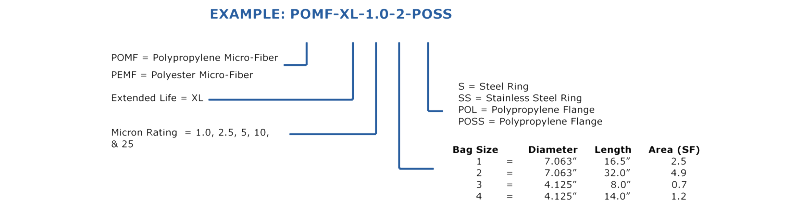

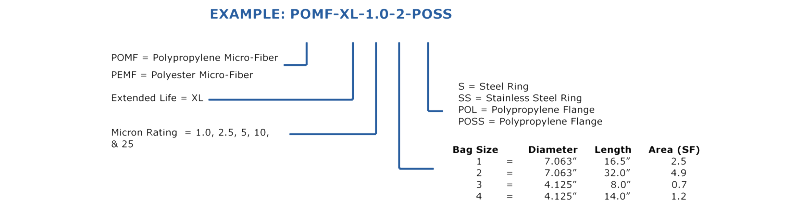

How to Order DHA Filter POMF 95 Series Bags

Filtration Levels

POMF/PEMF 95% Series liquid filter bags are absolute efficient at their suggested application rating.

Dirt Carrying Capacity

These High performance filter bags are rated using a challenge of AC Test dust in water, and controlled flow rate up to 10 GPM. Efficiency data represent initial efficiencies only.

Oil Holding Capacity

POMF (polypropylene) liquid filter bags can absorb unwanted trace of oils that occur in processed fluids.

FDA Acceptability for Food & Beverages

All materials of construction in the POMF/PEMF 95% Series liquid filter bag are listed as acceptable for potable and edible liquid contact according to CFR Title 21.

| PRODUCT NUMBER | SUGGESTED APPLICATION | RATING EFFICIENCY |

|---|---|---|

| POMF/PEMF-1.0 | 1.0 micron | 95.00% |

| POMF/PEMF – 2.5 | 2.5 micron | 95.00% |

| POMF/PEMF – 5.0 | 5 micron | 95.00% |

| POMF/PEMF – 10.0 | 10 micron | 95.00% |

| POMF/PEMF – 25.0 | 25 micron | 95.00% |

| MATERIALS OF CONSTRUCTION | ||

|---|---|---|

| COMPONENTS | POMF | PEMF |

| Filter Materials | Polypropylene | Polyester |

| Coverweb Material | Polypropylene | Polyester |

| Handles & Thread | Polypropylene | Polyester |

| Ring Type | Carbon or Stainless Steel Ring or Plastic Flange | |

| Bag Sizes | 1, 2, 3 & 4 – Call for additional sizes available. | |

| Silicone Free | Constructed of pure polypropylene and polyester, free of potentially damaging silicone oils. | |

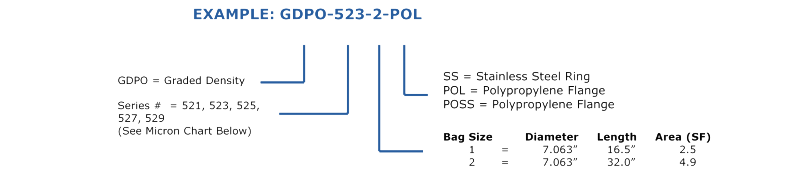

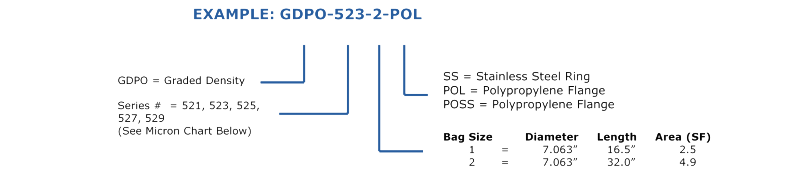

500 Series Graded Density Bags – 98% Efficiency

The 500 Series have approximately four times the dirt-holding capacity of our PEMF/POMF series bags at equivalent filtration levels. You can now use bags where performance levels previously required cartridges. These Graded Density Bags are made of multiple layers of microfibers and standard fibers variably calendared, providing filtration to 0.5 micron. Heavy-duty handles for ease in removal are available. The fully shaped bottoms enhance the pressure capacities of the bag.

The 500 Series has multiple layers of microfiber material, each layer with 4.4 sq. ft. of surface area.

The materials used to manufacture the 500 Series, graded density, 98% efficient filter bag comply with CFR Title 21 FDA regulations governing food and beverage contact.

Design Details

All Graded Density Bags have a 304 stainless steel retaining ring sewn in their opening. They make bag removal faster and easier.

The bags are sewn, and then turned inside out to avoid leakage through the threads. They are also made with sewn, fully-shaped bottoms to enhance the pressure capacities of thebags.

There are two sizes available. Size 1 is 7 inches by 16 inches. Size 2 is 7 inches by 32 inches.

The 500 Series, Graded Density filter bag materials comply with CFR Title 21 FDA regulations governing food and beverage contact.

How to Order DHA Filter 500 Series Bags

Filtration Levels

These bags have been tested by an independent laboratory to determine the filtration efficiency of the media used in each of the filter bags. The efficiencies for polyester and polypropylene are identical.

Dirt Carrying Capacity

Tests that were conducted using a size 2 bag and AC fine test dirt at 20 GPM, show dirt holding capacities for the following filtration ratings (at 20 PSI).

Oil Holding Capacity

In addition to contaminant removal, the Series 500 bags in poly- propylene will absorb trace oils that occur in fluids. This ranges from 100 grams per sq. ft. of filter material up to 400 grams per sq. ft. of filter media.

| MODEL NUMBER | 521 | 523 | 525 | 527 | 529 |

|---|---|---|---|---|---|

| EFFICIENCY | MICRON RATING | ||||

| 98.0% | 0.5 | 1.0 | 3.0 | 8.0 | 19.0 |

| 99.0% | 1.0 | 2.0 | 5.0 | 19.0 | 25.0 |

The test was conducted using AC file Test Dirt interfaced into clean water at 20 GPM

| MICRON RATING | MODEL | DIRT HOLDING CAPACITY (gms) | PRESSURE DROP |

|---|---|---|---|

| 0.5 | 521 | 237 | 2.5 PSI |

| 1.0 | 523 | 267 | 2 PSI |

| 3.0 | 525 | 296 | LESS THAN .50 PSI |

| 8.0 | 527 | 573 | LESS THAN .50 PSI |

| 19.0 | 529 | 870 | LESS THAN .50 PSI |

Pressure drop at 50 gpm flow (water) and specified micron rating using a Filter Technology, Inc. Model 8 (8-30) filter housing.

Reviews

There are no reviews yet.