It seems challenging to discover the best Industrial filter for your company. If we look, there are numerous features needs to think through while look over to the options for industrial purpose. The best Industrial filter has prominent features that include, amount of filtered water, environment, the flow rate of liquid, and size of pollutants present in water.

Many choices are existing for companies to choose the best Industrial filter. Companies want the best Industrial filter as they help in protecting the environment.

They have severe concerns related to industrial cleaners; for this, they rush to the industrial filtration specialist. This article will surely shed some light on factors for choosing the best Industrial filter.

1. Functional Settings:

The overall functioning of filters highly depends on temperature balance. Filters typically work on room temperature, but it should not reach to the excessive boiling point. There are also some facts to keep in mind while reviewing the functions of dust cartridge filter the USA and other types of industrial filters.

- The best Industrial filter observes the temperature of the liquid that is passing through the filter.

- Total Pressure in the filter

- The filter has to hold the volume, so test it before using the filter.

- Particle size must be in observation as it has passed across the filter.

2. Basic Filtration:

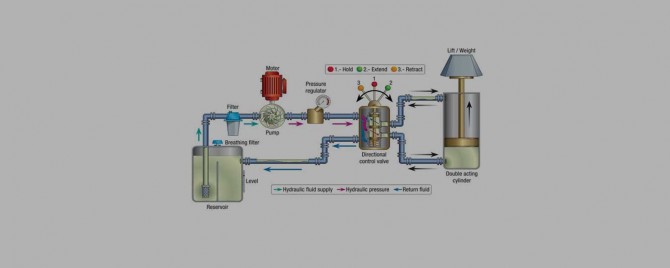

Filtration is the process that separates particles from liquid and gas streams. Figure out what needs to separate from the flow. The top filtration company suggests that kind of filters that eliminates underlying problems.

Gas and liquid filters somehow work in the same way, though it seems tricky to separate gas and liquid at the same time. Custom industrial filters are also the new invention picked by companies.

3. Chemical check:

The filter has two parts that filter element and filter housing. Therefore chemical balance in the liquid is the main issue faced while selecting an industrial filter. Reactivity of chemicals also impacts filters, and extreme temperature is not bound to chemical reactions. Yet chemical discharge can take place from the filter due to higher temperatures.

The variety of liquid passing through the filter should be checked and tested chemically. Industrial filters are proficient in eradicating all deferred solid particles and hydrocarbons without using any extra chemicals. Companies require the best industrial filter present in markets that that process the liquid effectively and quickly.

4. Visual check:

Physical feature matters, installation, or detaching of filter comprise on its physical feature. Its shape and quality. Proper configuration is a must (angle, diameter length, etc.).

Industrial filter manufacturers visually check the filter before installation. Usually, due to the wrong physical feature of filter production, needs have to suffer as it fails in understanding the amount of fluid that has to pass through. Be sure that when you begin to look for the best industrial water filtration companies, you do research and give time to look at every insight of the filter or filter companies.

Ask a question from others to investigate the best filter before leading to the final decision. When choosing a filter hold onto flow rate in mind, every type of filter is different from another, be it bag filter, walnut shell filters, or cartridge filter. Similarly, there are also extra vital points to keep in attention while choosing a filter for your company.

The filter provides different types of separation, so it’s good to know what we want from the filter.

- Classify all the possible chemicals that filter has to bare.

- Recognize environment settings and places where the filter is going to use.

- Physical contact is a must for filters in the companies.

- Check on regulatory defense services, who deliver filter maintenance and installation services.

However, directly else indirectly, water also considered as the reason for pollution, and that is the significant distress of companies.

Companies have to face serious harmful effects if they fail to control the contaminated or poisonous material spreading in the environment. To maintain desired standards of quality, companies look for high-quality industrial water plants.

In this modern era, the subject of the environment has brought into consideration linked with water usage at the industrial level. In the case of companies, industrial filters gain access, treat the liquid, and make sure that all produced waste of water runs into satisfactory standards of purification.

Wrapping Up:

It has verified that industrial filters are an energetic tool to save the environment. Excessive contaminated water pressure and rocky waste are the primary forms of the produced waste.

The primary facility of industrial filters is to take out all the impurities from the liquid, and it is one of the significant factors of industrial filters. Along with many industrial filter types contending for your company, always know your company’s necessity. Thus we have elaborated on how to choose the best industrial filters for your company. So, you can have better knowledge before choosing one.