Gas Turbine Cartridges

HEPA Grade Filtration

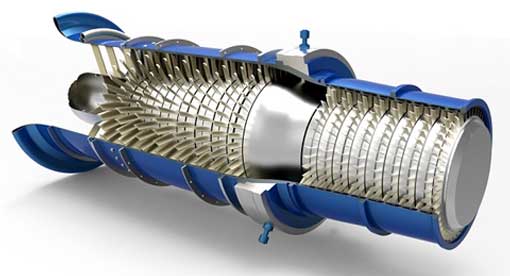

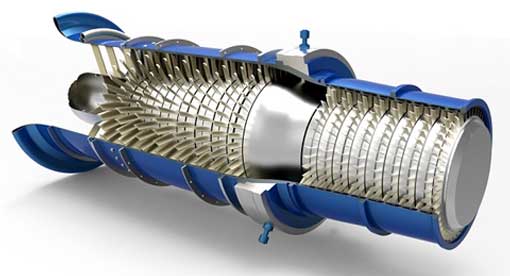

Gas turbines ingest a large amount of ambient air during operation. As a result, the quality of the air entering the turbine is a significant factor in the performance and life of the gas turbine.

As the costs and complexity of gas turbine generators increase, end users seek ways to both protect and maximize their investment. Many gas turbine operators have explored high efficiency options for their inlet filters. Switching to HEPA grade intake filtration greatly reduces the presence of contaminates in the turbine compressor. This helps extend turbine life and efficiency while reducing the costs in fuel and maintenance. There have been a few drawbacks to making the move to HEPA filters. One issue is that with a more restrictive filter media comes increased initial pressure drop. There have also been questions surrounding the long term durability and lifespan of the HEPA filters.

DHA Filter has developed a new line of intake filters that address many of these concerns. DHA’s Duraweb™ Elite line features a new 3 layer media that combines high efficiency filtration with durability and breathability.

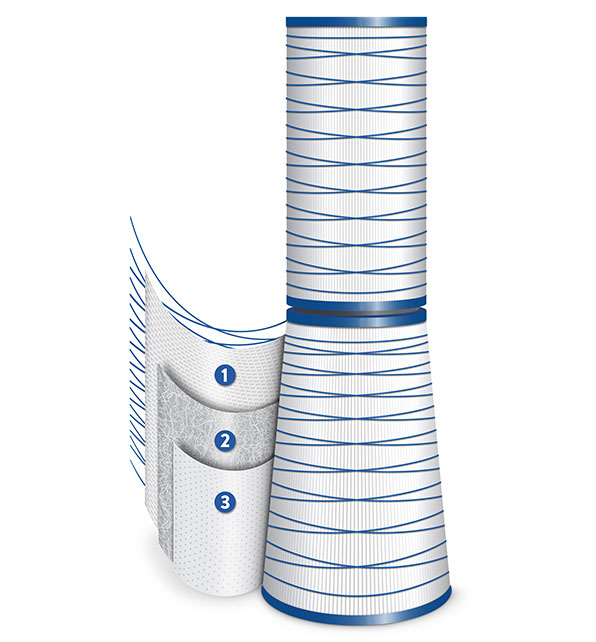

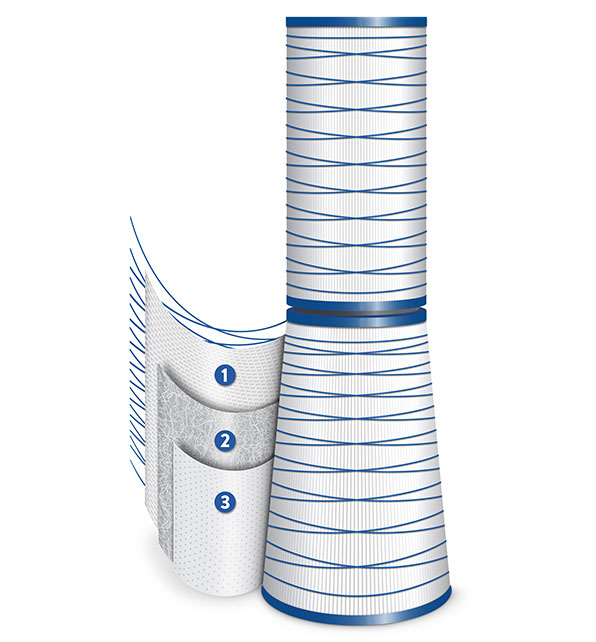

Media Technology – 3-Layer HEPA Grade ePTFE Membrane

Media construction starts with a hydro and oleo-phobic pre-filter barrier that prevents larger contaminants, salt chlorides, un-burnt hydrocarbons and moisture from contacting the membrane. Our proprietary second layer is an organically hydro-phobic ePTFE membrane that gives the filter its E12 efficiency while maintaining a low initial pressure drop. The thin “relaxed” membrane ensures flexibility and resiliency which affords the cartridge set to be pulse cleaned throughout the life of the filter. The membrane is thermally bonded to a bi-component polyester base through a unique process that forms a perma-bond membrane without the use of solvents, chemicals, or binders. The final layer improves overall strength and durability to keep your turbines operational for the long haul.

Layer 1 is our hydro/oleo-phobic pre-filter barrier for removal of larger particles, hydrocarbons and high humidity/moisture.

Layer 2 is our proprietary “relaxed” ePTFE membrane that delivers an E12 efficiency > 99.5% at MPPS. The membrane is inherently hydro-phobic for further protection against water ingress.

Layer 3 is our structural bi-component polyester layer which provides pack stability and rigidity, making the filter extremely resilient and pulse cleanable.

Media Filtration Properties:

- Duraweb™ Elite E12 efficiency > 95% at MPPS

- Pressure build-up over time is considerably slower than nanofiber media

- Lower coefficient of friction (non-penetrating of particulate)

- Zero moisture absorption (100% hydrophobic)

- Highest corrosion resistance media

- More durable than nanofiber

- Higher heat resistance than other membranes

- Highest rated media for chemical resistance

- Most chemically inert media on market

- Extremely weather tolerant (not affected by fog, salt deposit, high heat and extreme moisture)

- Electrostatic resistance (Insulator, no static build-up)

- High flexibility membrane

Positive Results for your Gas Turbine!

- Maximum power output from low pressure drop

- Increased fuel efficiency

- Increased production yield from elimination of unexpected shutdowns (due to fouling)

- Cost savings (lower resistance over time in comparison to nanofiber media)

- Increased operating hours with highest dust holding capacity (5,280g/filter)

- Eliminate downtime from offline water washings

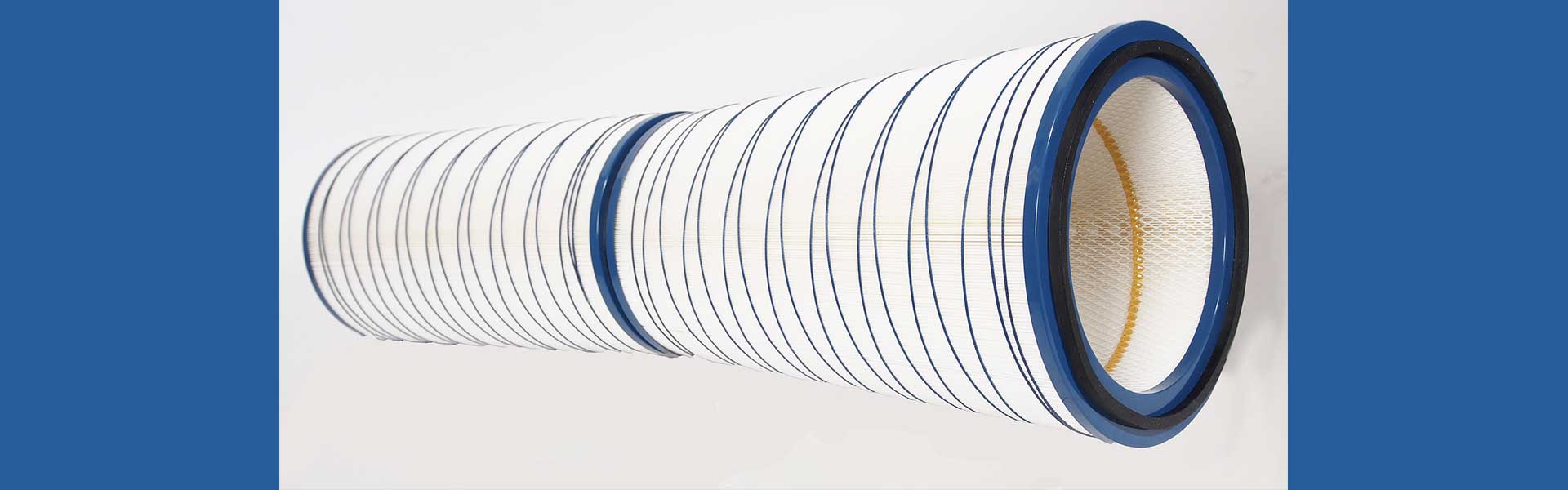

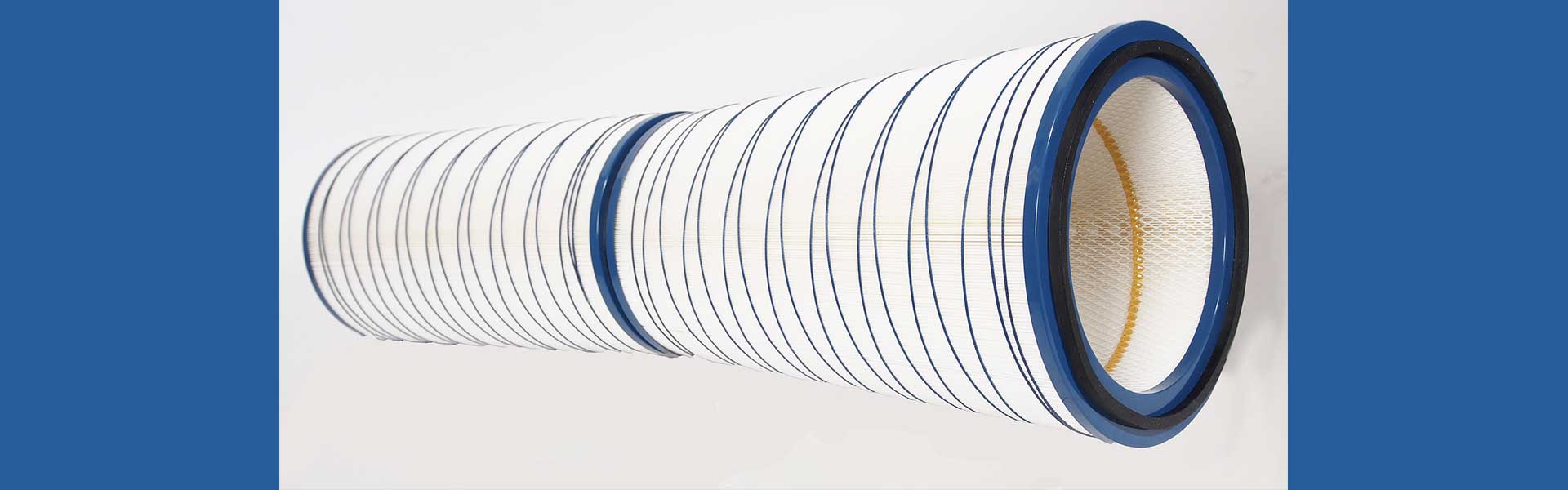

Filter Design

Filter design is extremely important for gas turbine cartridges. A natural collapse of pleats over time creates high pressure and low efficiency output. DHA Filter offers a unique Tri-Bead pleat locking system that virtually eliminates bridging and ensures 100% pleat exposure for the life of the filter.

First, the media is pleated using an integral hot melt glue bead to ensure perfect separation and breathability. Next, during the assembly phase, the media pack is securely fastened to the core by means of a thick glue bead to further improve stability during operation. Lastly, our proprietary helix bead wrap fundamentally locks the pleats in place promoting a consistently low pressure drop and long filter life.

Helix Bead Wrap

TRI-BEAD ADVANTAGES:

- Longer life expectancy from keeping pressure low over particulate build-up (1.5 to 3 times longer life due to zero pleat collapse)

- Reduced energy consumption by requiring fewer pulses to clean

- Environmentally friendly with no outer expanded metal cage – easy disposal

- Helix bead wrap offers 90% open surface area vs. 68% with an expanded metal cage

- Pleats are “locked” in place and will not deviate during operation

- Cartridge has better breathability and cleans more efficiently

- No media abrasion from contact with the expanded metal cage

Filtration is critical for turbine engines and has a direct relation to the performance and life of your rotating equipment. Advancing to DURAWEB™ Elite HEPA Grade cartridges have considerable benefits to your bottom line. Higher compressor efficiency and power output from less fouling due to salt and water ingress, reduced turbine wear and corrosion causing system imbalance and port blockage, and increased turbine availability from less downtime for compressor washings are all contributing factors.

Benefits :

Higher Compressor Efficiency and Power Output

- Less fouling

- Maintaining cleanliness

- Increased engine reliability

- Improved fuel efficiency

Reduced Turbine Wear and Corrosion

- Eliminate blocking of cooling ports that cause overheating

- Eradicate invasion of harmful airborne contaminants and moisture

- Prevent system imbalance from fouling

- Avoid expenses associated with engine damage

Increased Turbine Reliability

- Less downtime needed from off-line compressor washings

- Extend life of engine components

- Less risk of start up and shutdown failures

- Continuous dependable operation at high compressor efficiency