Baghouse Filters

We supply Baghouse Filters to fit a variety of collectors:

- Wheelabrator

- Ultrakleen

- Torit

- I.A.C.

- Carter Day

- Griffin

- Draco

- Dustex

- Micro-Pul

- Pangborn

- Pneumafil

- BHA

- Baldor

- Mac

- Banner

- American Air

- Airtrol

- StaClean

- McNeilus

- Stephens

- Envirotech

- Flex-Kleen

- Sweco

- Carborundum

For Pulse Jet, Reverse Air, and Mechanical Shaker cleaning systems.

DHA Filter offers a complete range of filter bags for dust collection systems in a wide assortment of fabrics, finishes, styles and sizes. We customize filtration fabrics to maximum filtration efficiency, dust cake release, and durability.

Changes to gas stream chemistry, moisture or hydrocarbons, and/or high temperature spikes, as well as operating conditions, need to be considered to maximize filter life and performance.

The style and construction of bags are typically determined by the collector cleaning system, and if support cages are needed.

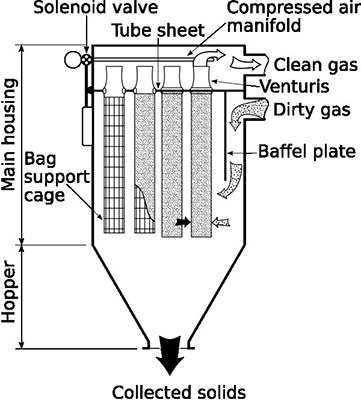

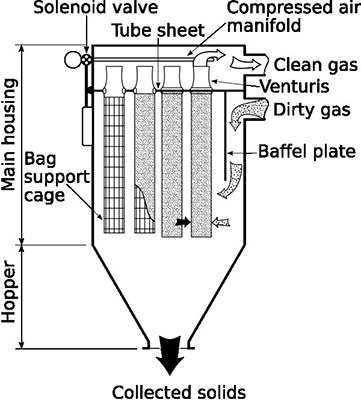

In Pulse-Jet baghouses, individual bags are supported by a metal cage (filter cage), which is fastened onto a cell plate at the top of the baghouse. Dirty gas enters from the bottom of the baghouse and flows from outside to inside the bags. The metal cage prevents collapse of the bag.

Bags are cleaned by a short burst of compressed air injected through a common manifold over a row of bags. The compressed air is accelerated by a venturi nozzle mounted at the reverse-jet baghouse top of the bag. Since the duration of the compressed-air burst is short (about 0.1 seconds), it acts as a rapidly moving air bubble, traveling through the entire length of the bag and causing the bag surfaces to flex. This flexing of the bags breaks the dust cake, and the dislodged dust falls into a storage hopper below.

Reverse pulse-jet dust collectors can be operated continuously and cleaned without interruption of flow because the burst of compressed air is very small compared with the total volume of dusty air through the collector. On account of this continuous-cleaning feature, reverse-jet dust collectors are usually not compartmentalized.

The short cleaning cycle of reverse-jet collectors reduces recirculation and redeposit of dust. These collectors provide more complete cleaning and reconditioning of bags than shaker or reverse-air cleaning methods. Also, the continuous-cleaning feature allows them to operate at higher air-to-cloth ratios, so the space requirements are lower.

A digital sequential timer turns on the solenoid valve at set intervals to inject air into the blow pipe and clean the filters.

| Pulse Jet | |

|---|---|

| Advantages | Disadvantages |

| High collection efficiency | Dry compressed air required |

| High air-to-cloth ratio (6 to 10 ft/min) | Restricted to low to medium temperatures |

| Aggressive cleaning action | Unable to function with high humidty gases |

| Continuous | |

| Strong woven bags | |

| Lower bag wear | |

| Smaller footprint required | |

| Bag changing without entering baghouse | |

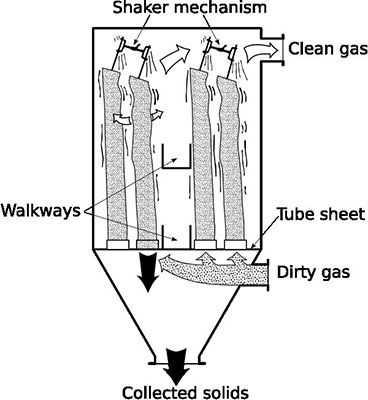

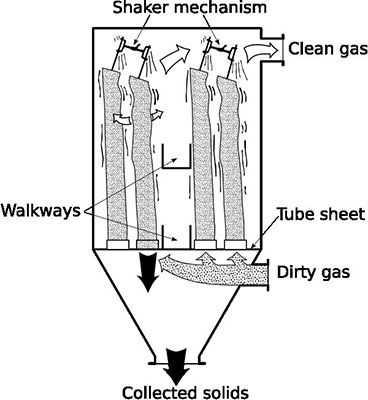

In Mechanical-Shaker baghouses, tubular filter bags are fastened onto a cell plate at the bottom of the baghouse and suspended from horizontal beams at the top. Dirty gas enters the bottom of the baghouse and passes through the filter, and the dust collects on the inside surface of the bags.

Cleaning a mechanical-shaker baghouse is accomplished by shaking the top horizontal bar from which the bags are suspended. Vibration produced by a motor-driven shaft and cam creates waves in the bags to shake off the dust cake.

Shaker baghouses range in size from small, handshaker devices to large, compartmentalized units. They can operate intermittently or continuously. Intermittent units can be used when processes operate on a batch basis; when a batch is completed, the baghouse can be cleaned. Continuous processes use compartmentalized baghouses; when one compartment is being cleaned, the airflow can be diverted to other compartments.

In shaker baghouses, there must be no positive pressure inside the bags during the shake cycle. Pressures as low as 5 pascals (0.00073 psi) can interfere with cleaning.

The air-to-cloth ratio for shaker baghouses is relatively low, hence the space requirements are quite high. However, because of the simplicity of design, they are popular in the minerals processing industry.

| Mechanical-Shaker | |

|---|---|

| Advantages | Disadvantages |

| High collection efficiency | Low air-to-cloth ratio (1.5 to 2 ft/min) |

| Strong woven bags | Restricted to low temperatures |

| Easy operation | Larger footprint required |

| Larger number of bags required | |

| Frequent maintenance | |

| Operaters must enter baghouse to change bags which creates potential toxic dust exposure |

|

| Poor cleaning efficiency if positive pressure present | |

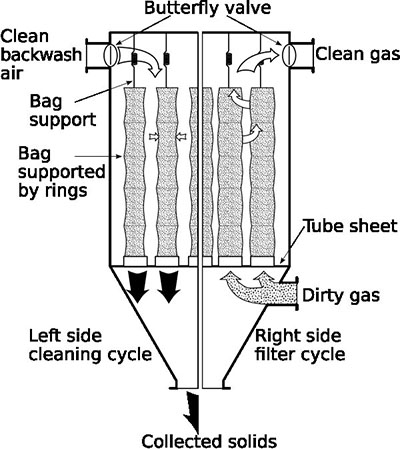

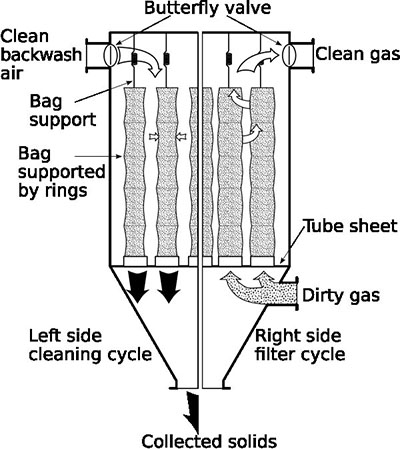

In Reverse-Air baghouses, the bags are fastened onto a cell plate at the bottom of the baghouse and suspended from an adjustable hanger frame at the top. Dirty gas flow normally enters the baghouse and passes through the bag from the inside, and the dust collects on the inside of the bags.

Reverse-air baghouses are compartmentalized to allow continuous operation. Before a cleaning cycle begins, filtration is stopped in the compartment to be cleaned. Bags are cleaned by injecting clean air into the dust collector in a reverse direction, which pressurizes the compartment. The pressure makes the bags collapse partially, causing the dust cake to crack and fall into the hopper below. At the end of the cleaning cycle, reverse airflow is discontinued, and the compartment is returned to the main stream.

The flow of the dirty gas helps maintain the shape of the bag. However, to prevent total collapse and fabric chafing during the cleaning cycle, rigid rings are sewn into the bags at intervals.

Space requirements for a reverse-air baghouse are comparable to those of a shaker baghouse; however, maintenance needs are somewhat greater.

| Reverse-Air | |

|---|---|

| Advantages | Disadvantages |

| High collection efficiency | Low air-to-cloth ratio (1 to 2 ft/min) |

| Preferred for high temperatures | Frequent maintenance |

| Unable to remove residual dust build up | |

| Clean exhaust air must be filtered | |

| Frequent maintenance | |

| Operaters must enter baghouse to change bags which creates potential toxic dust exposure |

|

Dust Bags

Engineered for durability and extended life, materials are selected based on abrasion resistance, chemical compatibility, temperature resistance, cake formation, efficiency and cleanability.

Available Fabrics:

- Polypropylene

- Teflon

- Wool

- Polyester

- Nomex

- Cotton

- Nylon

- Ryton

- Glass

- Acrylic

- PTFE

- Ceramic

Plenum Pulse and Pulse-Jet bag top and bottom designs

Pulse-jet and plenum pulse bag houses collect dust on the outside of the filter. Dust-laden gas floods the bag house, and clean air exits through the inside of the bag while the dust particles collect on the outside filter surface. A support cage prevents bag collapse during filtration and aids in the redistribution and cleaning of the dust cake. A wide variety of filter bags can be manufactured to meet specific application needs.

Filter bags for Reverse Air or Shaker designs

Particulate is collected on the inside surface of the bag in bag houses using reverse air or shaker cleaning systems. The dust-laden gas enters through the dirty side (inlet) of the collector and flows up through the bag. The particulate is filtered by the dust cake and the fabric, and clean air exits through the outside of the bag. Shaker and reverse air bag top and bottom designs vary by cleaning system and original equipment manufacturer (OEM).

Pleated Bags

Pleated bag filters are engineered to fit various size dust collectors and are fabricated to ensure ease of installation and change-out. They are easily mounted into various size cell plates for both top and bottom load dust collectors. Replaces fabric bag filters and cages used in many dust collectors.

- Ease of Installation

- Reduced Maintenance Cost

- Efficiencies up to 99.97%

- Higher Air Flow Per Filter Unit

- Fewer Change-Outs

- Better Resistance to Inlet Abrasion

- Up to a 5-Fold Increase in Surface Filtration

- Washable Exterior

- Minimizes Compressed Air Usage