It is impossible to ignore the significance of water and its purification in our lives. Since the water supply around the globe has to pass through other materials like minerals, chemicals, and human-made poisons.

That makes the water undrinkable and needs to be treated through some purification processes.

The process of subtraction of contaminants from the liquid is known as Filtration. it is also employed to get rid of unwanted fluids, like oil or vapor, from water.

Filters are the medium that carried out the filtration process. They are beneficial to clear the impurities which may be in the form of solid, liquid or gas which is unaware of the following process.

The water treatment may have different filtration techniques at different locations, because of water type and also depends on the plant’s technology. So, it is better to dig about them and learn new techniques.

THE BEST FILTRATION TECHNIQUES

1. Hot Filtration

Hot filtration technique is required when a few elements in the liquid get crystallized. If crystals start to grow, they will possibly disturb the whole filtration process by clogging the funnel.

Therefore, when such kind of fluid is being processed, it is essential to raise its temperature throughout filtration to stop crystallization. To avoid the formation of crystal in the liquid its important to speed up the process.

Fluted filter paper and stemless filter funnel are suggested to carry out this filtration process.

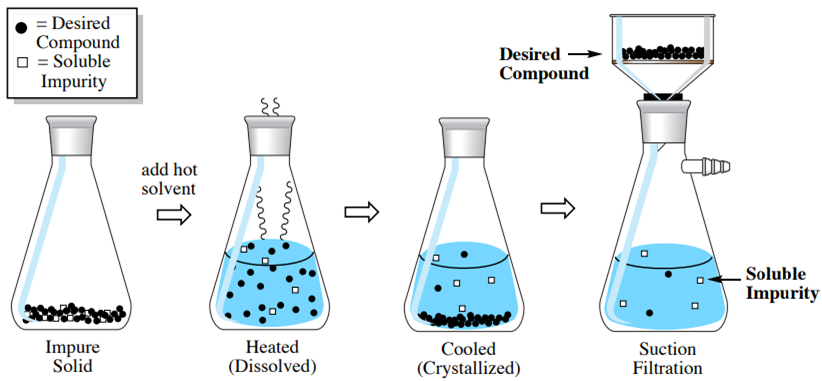

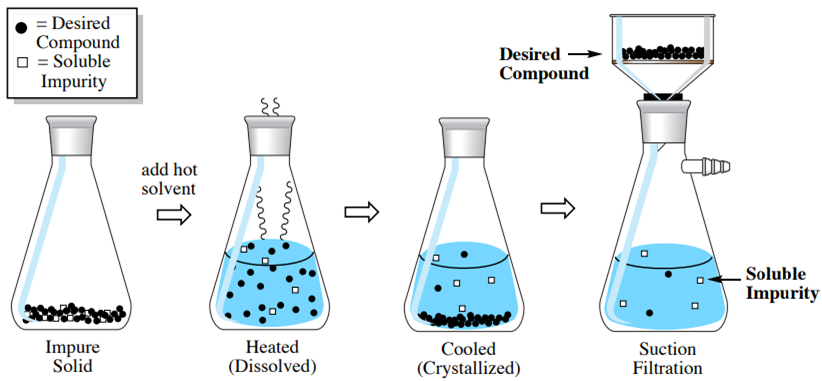

2. Cold Filtration

Its name itself telling that this filtration technique is the vice versa of hot filtration. In this case, the liquid has to cool down quickly to speed up the formation of the crystals which can be detached later.

This method is applied to create clusters of protein that can be removed afterward especially in the cocktail industry. A nanofiber filter is commonly used in this technique.

3. Mechanical Filtration

This process is an up-to-date method and is most extensively used in industrial filtration. In mechanical filtration based on forcing the fluid through a professional industrial filter element to get rid of or separate deferred solids from the liquid.

The force is applied by a pump, the more often used filter elements for mechanical filtration process filtration cartridges, bag filters, porous sintered metal elements, filter pads, and filter cloth.

4. Gravity Filtration

This is known as the simplest form of filtration, generally used in chemical test centers. The process contains placement of a filter paper in the funnel which is static on an iron ring and liquid is transferred into the funnel.

As the liquid passes through the filter paper, it gets collected in a beaker placed underneath. The solids which are bigger than the pores of the filter paper will get stuck in the paper. Meanwhile, the gravitational force is applied to let fluid reach downwards that is why this whole filtration technique is known as gravitational process

5. Vacuum Filtration

The process of vacuum filtration is slightly similar to gravity filtration in that a funnel is required with a filter paper immovable into it and the liquid is made to cross through the paper.

The only difference is that you need a specific flask to gather the filtrate, the flask is connected to an aspirator or a vacuum line with the help of a tube.

Through turning the vacuum on, the liquid is pushed into the flask through filter paper. This process is faster and more efficient than other types of filters.

6. Centrifugal Filtration

These filtration techniques are carried out by applying centrifugal force, which is an inertial force practiced by an object moving on a circular path, which leads it away from the center of rotation because of the force.

Due to the force formed by fast rotations of the drum, the deferred solids travel away from the center and get surrounded onto the walls of the equipment forced the liquid to get out.

7. Granular Media Filtration

This is a conservative filtration technique which quite obsolete. In this process, the liquid is supposed to pass through the surface of granular media like sand, gravel, or activated carbon.

The suspended solids get stuck within the non-woven filter media and you get is disinfected deposit. Most of the water treatment and wastewater treatment plants use this type of filtration system in the initial stages of purification.

Conclusion.

Now a day’s filtration is the common technique to obtain clean and pure water. These some best techniques have made the water consumption easy and fast. These techniques are highly utilized by all kinds of industries. Humans are intelligent to develop different water treatment techniques to make our water source to be harmless to drink. Although some methods are not operative on a larger scale.