The Earth and its temperatures can never be controlled or adjusted by man. However, there is always another way. We have gained control of our indoor environment by creating numerous equipment. Such are air conditioners, heat pumps, and window units, to name a few. And to keep these appliances working well, we have also invented different types of HVAC filters.

These filters are a crucial part of the cooling or heating appliances like the air conditioners, heat pumps, window units, and furnace units. The HVAC filters not only filter out larger particles or dust but pollen and tiny particles that can cause massive damage to your HVAC systems. Precisely, HVAC filters keep your air clean while protecting your HVAC systems as well.

HVAC systems are also primarily required for large or medium scale manufacturing as a lot of heat and dust is produced in the process. In this article, we will provide you with all the information you need about different types of HVAC filters so you can choose the best as per your requirements.

Types of HVAC Filters for Industrial Filtration

In heavy manufacturing units, heat, dust, and other pollutants become a considerable concern. Therefore, industrial filtration requires the best HVAC filters to keep the atmosphere of the factories in good condition at all times. Let’s discuss the different types of HVAC filters to help you find the one that suits your needs.

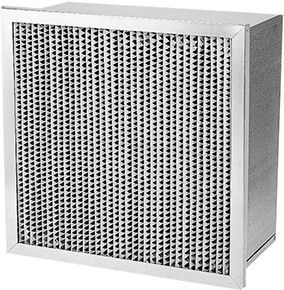

1. HEPA Filters

These are the mechanical type of air filters for HVAC systems. Its function involves pushing the air through a fine mesh to trap any pollutants, including dust, small and large particles. It also filters out the pollen, dust mites, tobacco smoke, and other contaminants that can be hazardous to health.

HEPA filters are known as the best types of HVAC filters, used in industries where there is a high need for controlling any contamination. These industries may include manufacturers of medical equipment, food items, and pharmaceutical products, to name a few. There are six types of these air filters, each with their own distinct characteristics.

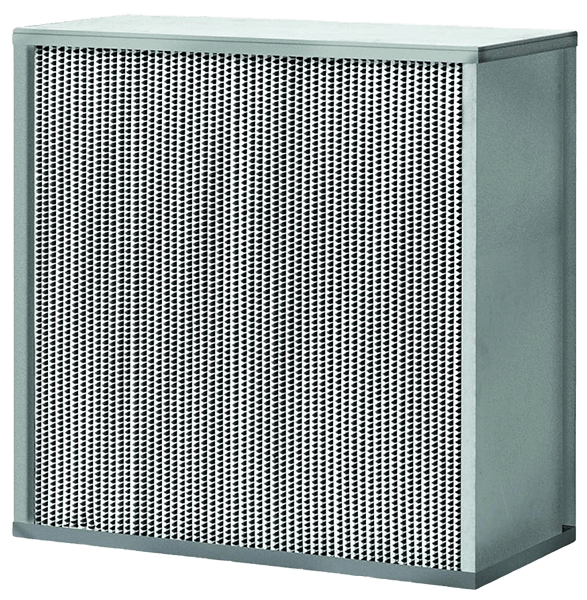

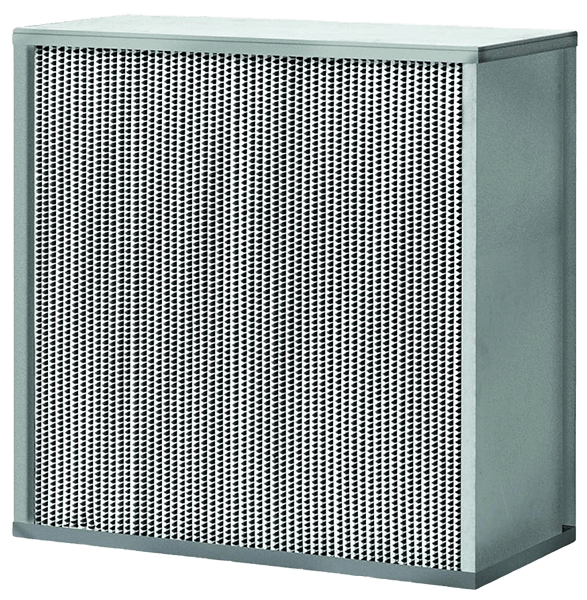

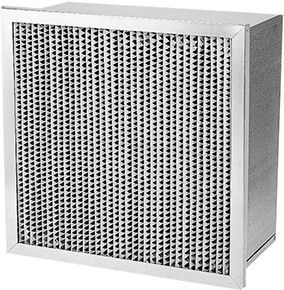

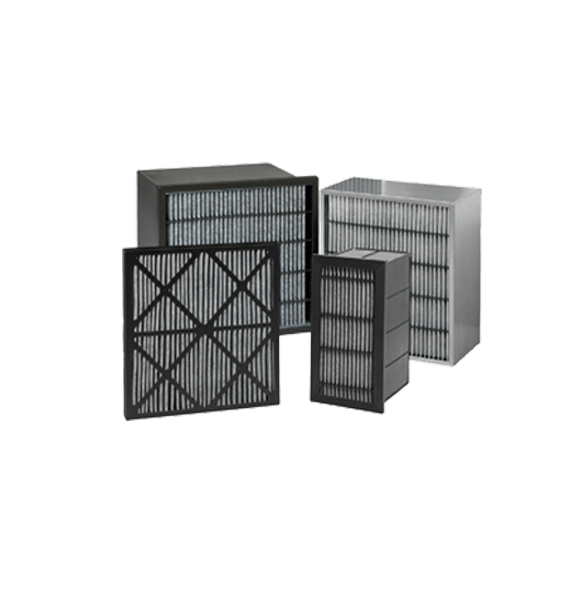

2. Box Filters

Box Filters are built with a rigid structure and a galvanized frame for heavy industrial use. These filters are lined with a ceaseless nanofiber media that ensures the unloading of dust. They can be used in industries where there is a high possibility of moisture involved in the process or suspended in the air.

With the wet-laid microfiber media, box filters resist any moisture to pass through. High levels of humidity for longer periods can cause mold, which has several health hazards, putting your employees’ lives at risk. Using this type of air filter, you can save your manufacturing units from excess moisture and the problems that arise due to it.

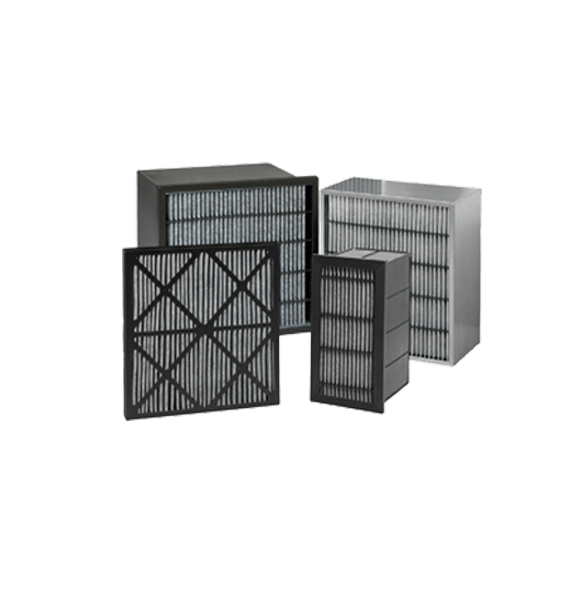

3. V-Bank Filters

V-Bank filters are known for their V-shaped structure that allows large amounts of air to enter due to a broader intake area. Its peculiar shape helps trap the contaminants far more efficiently than any other air filters can. These filters are utilized as main filters in industrial and commercial use due to their high efficiency.

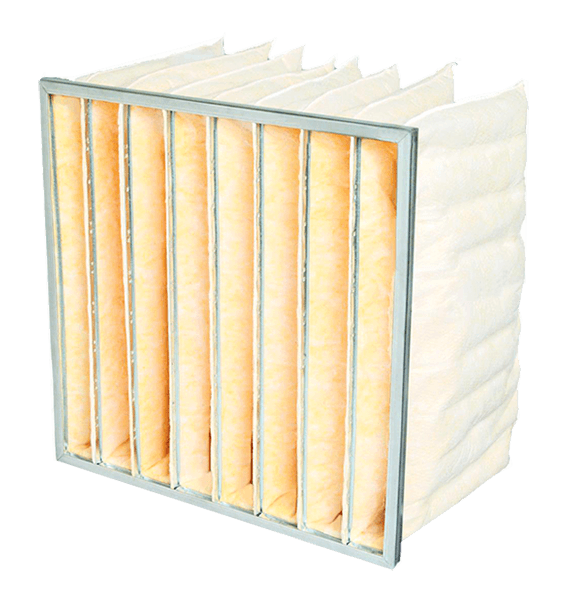

4. Pocket Filters

These are used to filter solid particles that are present in the gases. Its efficiency in filtering the dust particles is relatively higher than other types of filters. The decontaminated gas can be used in a variety of applications. They are ideal for use in processes where the particles are unusually resistant. Pocket Filters are used in the pharmaceutical industry as prefilters for HEPA and as final filters for commercial use.

5. Gas-Phase Filters

Gaseous air contaminants can be hazardous for the health of the workers present in a manufacturing unit. For that, gas-phase filters are used to cleanse the atmosphere and remove undesirable odors. These filters are equipped with chemical layers in its filter cartridge that is designed to remove pollutant gases from the air.

These can be used in data centers, libraries, food processing facilities, pulp, and paper industries, and fertilizer production, to name a few. Every manufacturing process where chemical treatment has to be done can result in gases that can corrode the machine and equipment. Therefore, the gas phase filter is one of the most important types of filters under the HVAC filter classification.

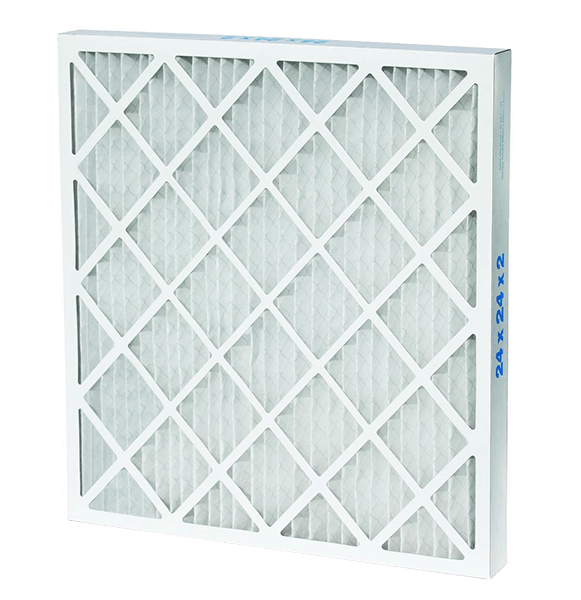

6. Pleated Air Filters

Pleated air filters are similar to fiberglass air filters; however, their resistance is much higher to the flow of air and dust-trapping abilities. These help in effectively removing irritants from the air like pollens, mold, dander, and dust. Their application can be made in different industries like pharmaceuticals, steel & power, powder coating, cement, chemicals, metals, minerals, and paint production.

Conclusion

The air that we breathe is the most critical component of life that why you have to pick the best types Of HVAC Filters. It should not be contaminated with any pollutants that can affect our health. Not only is contaminated air terrible for human health but the equipment and machinery that are present in medium or large scale manufacturing factories. Therefore, HVAC air filters must be used to keep the air clean.